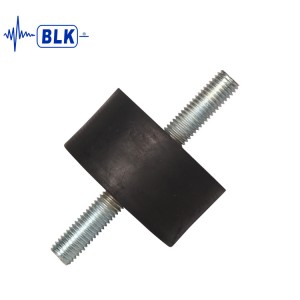

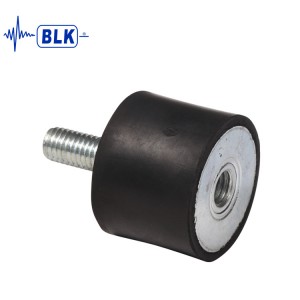

BKVV Type Anti-vibration Rubber Mounts

Description

Standard cylindrical mounts are made of high strength natural rubber materials, iron parts through special surface treatment, and rubber bonding height can reach 40KG/C2. Cylindrical mounts, also called cylindrical bobbins or bobbin mounts are commonly used for both active and passive vibration suppression as well as shock and structure-borne noise control. They can be loaded either in compression or shear taking into consideration individual demands for actual applications.The natural rubber cushion is chemically combined with steel, which has excellent wear resistance and high tensile strength. Rubber hardness choice, conventional 40, 60, 70 options.

With good fatigue resistance and durability, suitable for all kinds of small motor, water pump, motor, centrifuge and other vibration equipment. Easy installation, complete specifications, 8mm-150mm outside diameter size can meet various types of equipment selection.

These rubber mounts’ resilience and their broad range of different sizes and dimensions allow these mounts to be used in many applications that require noise and vibration isolation.

The size of this product can also be customized, please contact us for specific customization details.

Features

The rubber mount is made by high strength of natural rubber, the metal part with special surface treatment, the bonding strength is up to 40kg/C. The fatigue life is very good, suitable for all kinds of small generator, pump, motor and centrifugal machine. The installation is simple and the specification is wide. Outer diameter with 8mm to 150 mm can meet all kinds of isolated equipment.

● Metalwork: mild steel, plated.

● Natural rubber, bonded, cylindrically shaped.

● The design of the BKVV Type rubber mounts gives the following basic characteristics:

* Radial elasticity greater than axial elasticity.

* The rubber works in compression/shear according to the fixing method.

● Simple to fix

Applications

Fans, Motors, Compressors, Air conditioning, Electric Equipment, Automotive Equipment, Pumps, Computers, Control Panels, Generators,etc.

Product Parameter

|

Type |

A |

B |

Screw |

Load Capacity/KG |

Maximum Compression(mm) |

|||

|

C |

H |

40 degrees |

60 degrees |

|||||

|

BKVV8*8 |

8 |

8 |

M3 |

6\10 |

4 |

8 |

1.5 |

|

|

BKVV10*8 |

10 |

8 |

M3 |

M4 |

6\10 |

5 |

10 |

1.5 |

|

BKVV10*10 |

10 |

10 |

M3 |

M4 |

6\10 |

5 |

10 |

2 |

|

BKVV10*15 |

10 |

15 |

M3 |

M4 |

6\10 |

5 |

10 |

2 |

|

BKVV15*8 |

15 |

8 |

M3 |

M4 |

10\12\15 |

10 |

18 |

2 |

|

BKVV15*10 |

15 |

10 |

M3 |

M4 |

10\12\15 |

10 |

18 |

2 |

|

BKVV15*15 |

15 |

15 |

M3 |

M4 |

10\12\15 |

10 |

18 |

2 |

|

BKVV15*20 |

15 |

20 |

M3 |

M4 |

10\12\15 |

10 |

18 |

2 |

|

BKVV15*30 |

15 |

30 |

M3 |

M4 |

10\12\15 |

10 |

18 |

2 |

|

BKVV20*8 |

20 |

8 |

M6 |

8\10\16 |

10 |

20 |

1.5 |

|

|

BKVV20*10 |

20 |

10 |

M6 |

8\10\16 |

10 |

20 |

1.5 |

|

|

BKVV20*15 |

20 |

15 |

M6 |

8\10\16 |

13 |

25 |

2 |

|

|

BKVV20*20 |

20 |

20 |

M6 |

8\10\16 |

13 |

25 |

2 |

|

|

BKVV20*25 |

20 |

25 |

M6 |

8\10\16 |

15 |

28 |

2 |

|

|

BKVV20*30 |

20 |

30 |

M6 |

8\10\16 |

22 |

35 |

2.5 |

|

|

BKVV25*10 |

25 |

10 |

M6 |

M8 |

10\15\23 |

13 |

25 |

1.5 |

|

BKVV25*15 |

25 |

15 |

M6 |

M8 |

10\15\23 |

17 |

33 |

2 |

|

BKVV25*20 |

25 |

20 |

M6 |

M8 |

10\15\23 |

17 |

33 |

2 |

|

BKVV25*25 |

25 |

25 |

M6 |

M8 |

10\15\23 |

17 |

33 |

2 |

|

BKVV25*30 |

25 |

30 |

M6 |

M8 |

10\15\23 |

21 |

41 |

2.5 |

|

BKVV30*15 |

30 |

15 |

M8 |

16\20\23 |

22 |

40 |

2 |

|

|

BKVV30*20 |

30 |

20 |

M8 |

16\20\23 |

22 |

40 |

2 |

|

|

BKVV30*25 |

30 |

25 |

M8 |

16\20\23 |

22 |

40 |

2 |

|

|

BKVV30*30 |

30 |

30 |

M8 |

16\20\23 |

28 |

50 |

2.5 |

|

|

BKVV30*40 |

30 |

40 |

M8 |

16\20\23 |

28 |

50 |

2.5 |

|

|

BKVV40*20 |

40 |

20 |

M8 |

M10 |

16\20\23 |

26 |

48 |

2 |

|

BKVV40*25 |

40 |

25 |

M8 |

M10 |

23\27 |

26 |

48 |

2 |

|

BKVV40*30 |

40 |

30 |

M8 |

M10 |

23\27 |

32 |

60 |

2.5 |

|

BKVV40*40 |

40 |

40 |

M8 |

M10 |

23\27 |

38 |

72 |

3 |

|

BKVV50*20 |

50 |

20 |

M10 |

M12 |

23\27 |

30 |

56 |

2 |

|

BKVV50*25 |

50 |

25 |

M10 |

M12 |

23\27\32 |

30 |

56 |

2 |

|

BKVV50*30 |

50 |

30 |

M10 |

M12 |

23\27\32 |

38 |

70 |

2.5 |

|

BKVV50*35 |

50 |

35 |

M10 |

M12 |

23\27\32 |

38 |

70 |

3 |

|

BKVV50*40 |

50 |

40 |

M10 |

M12 |

23\27\32 |

45 |

85 |

3 |

|

BKVV50*45 |

50 |

45 |

M10 |

M12 |

23\27\32 |

45 |

85 |

3 |

|

BKVV50*50 |

50 |

50 |

M10 |

M12 |

23\27\32 |

45 |

85 |

2.5 |

|

BKVV60*30 |

60 |

60 |

M10 |

M12 |

23\27\32 |

60 |

110 |

2.5 |

|

BKVV60*35 |

60 |

30 |

M10 |

M12 |

27\32\37 |

60 |

110 |

2.5 |

|

BKVV60*40 |

60 |

40 |

M10 |

M12 |

27\32\37 |

60 |

110 |

3 |

|

BKVV60*45 |

60 |

45 |

M10 |

M12 |

27\32\37 |

72 |

132 |

3 |

|

BKVV60*50 |

60 |

50 |

M10 |

M12 |

27\32\37 |

72 |

132 |

3 |

|

BKVV60*60 |

60 |

60 |

M10 |

M12 |

27\32\37 |

72 |

132 |

3.5 |

|

BKVV70*65 |

70 |

65 |

M12 |

M16 |

37\42 |

160 |

280 |

2 |

|

BKVV70*25 |

75 |

25 |

M12 |

M16 |

37\42 |

100 |

180 |

3 |

|

BKVV70*40 |

75 |

40 |

M12 |

M16 |

37\42 |

150 |

270 |

3 |

|

BKVV70*45 |

75 |

45 |

M12 |

M16 |

37\42 |

150 |

270 |

3 |

|

BKVV70*50 |

75 |

50 |

M12 |

M16 |

37\42 |

150 |

270 |

3.5 |

|

BKVV70*55 |

75 |

55 |

M12 |

M16 |

37\42 |

175 |

315 |

3 |

|

BKVV80*40 |

80 |

40 |

M12 |

M16 |

42\47 |

150 |

280 |

3 |

|

BKVV80*50 |

80 |

50 |

M12 |

M16 |

42\47 |

175 |

280 |

3.5 |

|

BKVV80*60 |

80 |

60 |

M12 |

M16 |

42\47 |

205 |

325 |

4 |

|

BKVV80*80 |

80 |

80 |

M12 |

M16 |

42\47 |

235 |

370 |

2.5 |

|

BKVV100*30 |

100 |

30 |

M12 |

M16 |

42\47 |

190 |

350 |

3 |

|

BKVV100*40 |

100 |

40 |

M16 |

42\47 |

230 |

420 |

3 |

|

|

BKVV100*45 |

100 |

45 |

M16 |

42\47 |

230 |

420 |

3 |

|

|

BKVV100*50 |

100 |

50 |

M16 |

42\47 |

230 |

420 |

3 |

|

|

BKVV100*55 |

100 |

55 |

M16 |

42\47 |

270 |

490 |

3.4 |

|

|

BKVV100*60 |

100 |

60 |

M16 |

42\47 |

310 |

560 |

4 |

|

|

BKVV100*75 |

100 |

75 |

M16 |

42\47 |

310 |

560 |

4 |

|

|

BKVV100*100 |

100 |

100 |

M16 |

42\47 |

390 |

700 |

5 |

|

|

BKVV150*75 |

150 |

75 |

M16 |

M20 |

42\47 |

750 |

1400 |

5 |