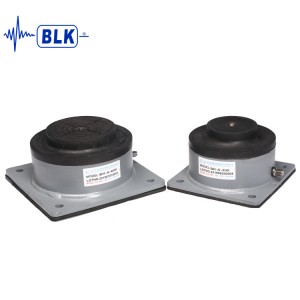

BK-A Type Pneumatic Isolator/Air-spring Mounts

Description

BK-A type anti-vibration air mounts are used for efficient vibration isolation of mechanical equipment and assemblies to prevent vibration caused by shock and oscillation effects. Needle parts are manufactured from quality synthetic rubber and are constructed to allow for efficient vibration isolation without horizontal deformation. The rubber air mounts substrate is equipped with non-slip pads, eliminating the need to anchor the machine to the ground.

Features

● Pneumatic vibration proof device, in line with JISD-4101 pressure test standards.

● The natural frequency is 3Hz~5Hz, and the working pressure is 4.5kg /cm^2.

● The body is made of Neoprene Rubber, and the integral molding has good air tightness.

● Anti - vibration effect is good, the general equipment efficiency can reach about 97%.

● Load range 50~9000 kg.

● Oil proof cap can be installed to prevent general oil corrosion.

Applications

It is very suitable for vibration isolation of high speed electric press, water pump, vibration plate, screw machine, punch press and other machines with high dynamic force. Passive vibration isolation for measuring and testing equipment.

Product Parameter

|

Type |

Rated Capacity (Kg) |

Dimensions (mm) |

Bolt |

||||||

|

A |

B |

C |

H |

ΦD |

Φd |

ΦBD |

|||

|

BK-A-040 |

30-40 |

76 |

60 |

0 |

65 |

74 |

25 |

7 |

M10 |

|

BK-A-050 |

30-50 |

76 |

60 |

0 |

62 |

72.5 |

26 |

7 |

M10 |

|

BK-A-090 |

50-100 |

125 |

100 |

0 |

100 |

100 |

60 |

12 |

M12 |

|

BK-A-150 |

100-200 |

125 |

100 |

0 |

100 |

100 |

60 |

12 |

M12 |

|

BK-A-300 |

200-400 |

160 |

125 |

0 |

100 |

138 |

80 |

14 |

M12 |

|

BK-A-600 |

400-700 |

200 |

160 |

0 |

100 |

164 |

110 |

14 |

M12 |

|

BK-A-1100 |

900-1200 |

250 |

200 |

0 |

100 |

210 |

150 |

14 |

M16 |

|

BK-A-1900 |

1600-2000 |

350 |

300 |

0 |

100 |

314 |

240 |

14 |

M20 |

|

BK-A-3400 |

2800-3500 |

500 |

450 |

90 |

110 |

412 |

330 |

16 |

M20 |

Note:

1. The selected model cannot exceed its maximum load bearing capacity.

2. It must be charged and deflated under load.

3. Tighten the bolts by hand instead of using wrenches, which may be damaged easily.

4. Fill with air nozzle in sections until reaching working height.

Installation

The air mounts is fixed in place with the equipment through bolts, and then inflated through the standard valve. The floating height is less than 10mm. The height of the air mounts can be adjusted by releasing and increasing the amount of air to adjust the levelness of the machine, and the highest adjustable height is 10mm.